About us

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain – from the raw materials to the finished product – and includes the latest rolling solutions for the non-ferrous metals sector. Primetals Technologies is a group company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide.

In Russia, Primetals Technologies is represented by Primetals Technologies Russia Limited Liability Company, consisting of two divisions in Moscow and Yekaterinburg.

The main division in the city of Moscow is engaged in general administration of the Company's work, and also conducts research and analysis of trends in the metallurgy market; develops the potential of the sales market in its region and in the channel for the distribution of the assigned products, solutions, and services; carries out sales and the achievement of the planned rate of return in accordance with the business strategy; provides sales support to the HQ in the Russian market; carries out visa support and provides translation services to the employees of Primetals Technologies Russia LLC and to other affiliated companies.

A separate subdivision in the city of Yekaterinburg is engaged in the design of electrical equipment and automation systems for ferrous and non-ferrous metallurgy. The subdivision's areas of activity also include the supply, assembly, and commissioning of automation systems for production and for machine control.

Over years of work, Primetals Technologies Russia LLC has managed to accumulate a lot of experience in executing both minor and major projects. Our client base comprises around 50 steel plants.

Our simple hierarchy and flexible business model make us constantly available. Around 80% of our employees have over 10 years of professional experience, which is a solid foundation for trust from our clients.

For us, the foremost significance lies in searching for the best solutions and satisfying the expectations of the clients and the market, in generating new ideas and bringing them to life in order to become a consistent leader in our industry.

Competences

Our expertise along the entire value chain

Digitalization — industry 4.0

Metals Orchestra – Instruments for the digital era of steel

Imagine your steel plant as an orchestra where all components work in harmony to manufacture products of highest quality. The “smart” plants of the future contain equipment that is interconnected and can be orchestrated with ease to deliver unparalleled efficiency and reliability.

Up to date with electrics and automation

The rising demand for flexible and efficient production processes results in a growing need for integrated electrics and automation solutions during the whole lifetime of metallurgical plants.

Primetals Technologies is the leading supplier of electrics and automation products, solutions and services for the metals industry. The objective is to help our customers optimize availability, profitability and product quality. The Electrical and Automation portfolio spans from basic process automation, power solutions and drives systems to technological process modelling and production planning. In addition we provide modernization packages and Lifecycle Services along the entire production chain. With our global EA setup we realize local support and long term-partnership with our customers to offer specific solutions & services based on our know-how and their individual requirements.

Lifecycle services for steel plants

Reliable technical support, plant upgrades, and proven maintenance services.

Primetals Technologies has the experience required to deliver the full spectrum of technical support, consulting, staff training, and next-level e-services quickly and reliably. We thrive on long-term partnerships with customers, and that’s why we can offer a set of dedicated services that are in place for the entire lifecycle of a steel plant. We are a full-service provider of technical support that includes upgrades, repairs, just-in-time spare parts, and on- and offline maintenance to keep steel plants operating at peak performance. Our service team can help steel plants to slash costs, increase productivity, improve product quality, and raise safety standards.

Eco solutions — saving resources, creating value

Due to rising energy prices and stringent environmental regulations, energy efficiency, resource saving and climate protection are becoming more important than ever. Primetals Technologies ECO Solutions offers a wide range of services and technologies to increase energy efficiency, reduce the environmental impact of steel production and to ensure efficient water and by-product management.

Primetals Technologies ECO Solutions provides processes and solutions along the entire iron and steel production chains, which meet the strictest emission regulations and also help producers achieve substantial cost savings. Further, in response to these ecological and economic challenges, Primetals Technologies offers energy-efficient solutions and services along the entire process chain, with a clear objective: saving resources, creating value. The optimized consumption of energy and raw materials, the application of advanced technological processes and the maximum degree of recycling lead to major energy savings, reduced emissions, improved water and by-product management.

Areas of activity

Primetals Technologies Russia LLC offers the following work and services:

- Research and analysis of trends in the metallurgy market;

-

Electrical systems engineering, medium and low voltage:

- Engineering of power distribution systems, control cabinets, and motor control centers, as well as control systems for medium-voltage alternating-current electric drives and low-voltage direct- and alternating-current electric drives.

- Basic engineering (collecting source data and revealing project specificities; establishing the main principles and requirements for carrying out design work), detailed engineering of E&A equipment and power supply / control systems (development of systems for process control and drive control; detail engineering for cabling), assembly engineering using CAD software: EPLAN, AutoCAD, SIGRAPH.

- Preparation of inquiries to design institutes for the development of design documentation for passing the State Expert Review (for projects in Russia).

-

Software engineering for Level 1 automation systems:

- Software engineering for Level 1 automation based on automation tools and software products from Siemens (STEP7, PCS7, WinCC, TIA-portal), as well as from Allen-Bradley, Schneider Electric, Omron, Wonderware.

- Integration and implementation of interfacing between all control systems in use.

- Preparation of instruction manuals for operators and operations personnel (on subjects such as: setup of software and information systems; description of methods for setting up equipment mechanically and electrically).

-

Software engineering for Level 2 automation systems:

- Software engineering for Level 2 automation based on software products C# (.Net), Java, C/C++, Oracle, MS SQL, CLC, VBA

- Data acquisition and storage systems, human-machine interface (HMI), user-friendly output of process parameters, reporting.

- Process modelling, long-term archiving, interfacing with other levels of general shop / general plant automation.

-

Site works:

- Installation supervision and commissioning, both in Russia and abroad.

- Consulting services.

- Training of the Customer's operations and process personnel.

- After-sales support.

-

Creating a digital twin of the production line:

- 3-D modelling of the shop space (arrangement of the lifting equipment and ground transport; transport route; specification of speed and load-related characteristics).

- Main process equipment (XYZ positioning of the main process equipment's points; specification of technical characteristics).

- Control and logistics (creating the process route; logistics simulation software, logistical operations efficiency analysis).

-

Creating hardware and software complexes:

- Automated control system for the technological process of collecting and storing converter gas (Gas holder).

Description of application software:

Application software for converter gas collection and storage system (Gas holder) is designed to control the installation of a gas tank at an industrial enterprise.

The cost of application software is calculated individually. For an accurate cost calculation, you can contact us using the contacts listed on the website.

For download:

Application software documentation (Gas holder)

Set of activities directed at commissioning the software and the APCS¹ information systems includes the following:

- checking the assembly of APCS equipment (PLCs²) in telecommunications cabinets;

- checking the assembly of the electric supply and grounding system;

- assembly and installation of IT equipment in server racks and its commissioning, as well as its connection to the electric network and backup power supply system;

- assembly of local network segment for data exchange between the PLCs (automation Level 1), distributed input / output systems (field level), HMI process visualization system, and the process automation system (Level 2);

- setup of network parameters for organizing communication with the PLCs / HMIs and the PCs / Server of automation Level 2;

- setup of the access rights of information system users;

- setup of special software and databases for organizing storage and distribution (routing) of emergency messages and archive values;

- correction of the existing databases with the setup and filling out of all catalogs;

- software setup, and making changes in the software where required, in accordance with the Software Change Manual, with the aim of optimizing software and eliminating its faults, in accordance with the project solutions (functional description, technical documentation);

- system software setup for operator stations (PCs) and optimization of application software for HMI process visualization;

- training the Customer's personnel within the framework of operating the automated control system (group classes for the Customer's personnel held in accordance with the training plan);

- correction of programs that make up the IS when they produce wrong results under the conditions of being limited by the Technical Assignment and the documentation;

- expansion of functional capabilities and improvement of the characteristics of solutions for specific tasks in accordance with the new or supplemented Technical Assignment.

*APCS – automated process control system

*PLC – programmable logic controller

Documentation

Certificates and licenses:

Watch in full

Certificate for the management system according to ISO 9001:2015

Watch in full

Extract from the register of members of the self-regulatory organization (project group)

Watch in full

Certificate of admission to certain types of work (construction group)

Watch in full

Registration certificate of the "Digital twin for steel-melting" software system

Policies:

News

- Primetals Technologies designed, installed, and will provide maintenance services for the new solution

- Upgrade increases safety, efficiency, and operational lifetime of a Nakata flying cutoff machine

- Project completed on time and to U.S. standards

Primetals Technologies and Nakata Mfg. have successfully completed the automation and drives system upgrade for a 12-inch Nakata flying cutoff machine at a major tubular products supplier in the southeastern United States. The project included design, installation, and commissioning of a new solution featuring an advanced Siemens programmable logic controller (PLC) with safety functions and drives. This upgrade enables the plant to operate the machine more safely and efficiently while increasing its operational lifetime.

Increased Safety

The new solution, developed by Nakata Mfg., features user-friendly flexible programming and enhanced machine safety. The PLC safety functionality includes the application of access control devices on safety gates around the machine perimeter, and the implementation of functional safety via the PROFIsafe protocol over the PROFINET communication network with Siemens Sinamics drives.

Nakata’s automation also utilizes edge computing, allowing each application to run on a virtualized system that can be seamlessly migrated to any other platform. This approach also allows easier access for support compared to traditional server/client applications. As an additional benefit, edge computing provides a framework for future system expansion, including cloud computing, data analytics, and artificial intelligence.

Completed on Schedule

Through a cooperation agreement, Nakata supplied the proprietary information required to engineer the new system, while Primetals Technologies contributed local expertise to ensure the engineering and equipment met U.S. standards. Primetals Technologies will also provide ongoing maintenance service support from its nearby location in Alpharetta, Georgia. The project was completed as scheduled with the machine returning to successful operation and production.

“Maintaining obsolete control systems is a huge challenge in the metals industry. Fortunately, we have years of experience servicing process equipment in the industry. We also have a long-standing partnership with Nakata. Together, these advantages provided the machine and process know-how required for a successful equipment upgrade.”

Luis Illan

Technical Sales Director, Primetals Technologies

- Primetals Technologies receives order for Level 1 and 2 automation system upgrade

- First installation of a state-of-the-art automation platform in India

- Startup scheduled for first quarter of 2026

Jindal Steel and Power (JSP) has tasked Primetals Technologies with supplying and implementing a comprehensive Level 1 and 2 automation system upgrade at its 5-meter plate mill in Angul, Odisha province, India. The upgrade will improve system availability and ensure a stable supply of spare parts.

First of its Kind in India

Primetals Technologies will supply new hardware and migrate the existing application software for the mill’s main rolling area. The upgrade includes the advanced SIMATIC S7-1500 control system and the latest WinCC software, both part of the totally integrated automation (TIA) portal. This marks the first-ever installation of this automation platform at a plate mill of this size in India.

The project also includes full virtualization of all servers, making lifecycle management of the automation infrastructure smoother and more efficient.

Designed for Shorter Downtime

JSP’s 5-meter plate mill has a capacity of 1.2 million tons annually and produces plates ranging from 5 to 350 millimeters in thickness and 900 to 4,800 millimeters in width. Key automation functions, including the human-machine interface (HMI), will be retained during the migration. As a result, operators and maintenance personnel will be familiar with the system from day one, allowing for a shorter ramp-up period and accelerating the return to full production.

Currently, the outdated automation system at the Angul site is a major cause of unwanted downtime for JSP. Installing the latest hardware and software will improve production stability and allow for seamless integration of future software packages and system updates.

A Global Player

Jindal Steel and Power (JSP) is a global industrial powerhouse with a strong presence in the steel, mining, and infrastructure sectors. With strategic investment worth USD 12 billion worldwide, JSP continues to expand its capacity and operational efficiencies, seizing opportunities to contribute to a self-reliant India.

As a leading steel manufacturer, JSP is committed to reducing its carbon footprint and pioneering sustainable practices, setting new benchmarks for responsible industrial growth.

- Enable thyssenkrupp Steel to produce high-strength steel grades and adapt to current and future market demands

- Advanced continuous slab caster with state-of-the-art process optimization systems ensures highly efficient casting

- Primetals Technologies awarded comprehensive service contract for slab caster

- Modernized hot-strip mill equipped with advanced automation solution for high quality, increased productivity, and stable operations

On July 4, 2025, thyssenkrupp Steel and Primetals Technologies have celebrated the successful startup of slab caster No. 4 and hot-strip mill No. 4, both supplied by Primetals Technologies, at thyssenkrupp’s Bruckhausen site in Duisburg, Germany. The ceremony was attended by political and industry leaders, including Mona Neubaur, Minister of Economic Affairs and Climate Protection, as well as top executives from both companies.

Flexible and Future-Proof Production

The project separated the former combined casting and rolling line into two distinct units: a revamped caster and a modernized hot-strip mill. As a result, thyssenkrupp Steel increased capacity from 1.8 to 3.1 million tons per year and aligned its product range with future markets and a focus on profitable premium products.

"This project is a decisive milestone in strengthening our leadership in technological and quality terms, while meeting the increasing expectations of our customers. We now possess one of the most modern production networks in the European steel industry. This will enable us to optimize our slab and hot-strip qualities significantly with the aim of further developing our product portfolio in line with future requirements, particularly in the case of multi-phase steels, high-strength steels, and grades for electric mobility and the energy turnaround.”

Dennis Grimm

CEO at thyssenkrupp Steel

“Over the past several months of construction work and commissioning, Primetals Technologies and thyssenkrupp Steel have worked closely together to reach this significant milestone. Our teams have definitely gone the extra mile—both on the construction site and throughout the planning and engineering phases—to ensure the success of this challenging project, all while operating under intense time constraints. I want to extend my heartfelt gratitude to all Primetals Technologies employees involved in the project for their outstanding dedication. I would also like to thank thyssenkrupp Steel and our partners for their expertise and support. This successful startup would not have been possible without our strong collaboration.”

Hans-Juergen Zeiher

Executive Vice President and Head of Global Business Unit Electrics and Automation at Primetals Technologies

The project faced several challenges, including a tight schedule and up to 1,000 workers on-site simultaneously. Thanks to close collaboration and strong project management, Primetals Technologies completed the project on time. As an example, the roughing mill and descaler were preassembled next to the existing line, allowing for rapid installation during the scheduled shutdown.

State-of-the-Art Slab Caster

The upgraded 2-strand continuous caster No. 4 processes slabs from 900 to 1,800 millimeters wide and 257 millimeters thick. It includes advanced mechanical and automation solutions. The DynaWidth mold-width adjustment system enables fast and flexible slab-width changes, while the DynaFlex hydraulic oscillator improves strand-surface quality by adjusting mold-oscillation parameters. The Level 2 automation system, CC Optimizer, features modules like Dynacs 3D, which ensures optimal secondary cooling.

New Caster Maintenance Contract

The partnership between thyssenkrupp Steel and Primetals Technologies has also led to a two-year maintenance contract for the ECO-star roller repair and services on caster No. 4. This agreement aims to stabilize production, extend roller lifetime, and ensure reliable operation. With the support of the Maintenance and Asset Technology (MAT) platform, a computerized maintenance management system, Primetals Technologies will provide comprehensive roller maintenance, including inspection, refurbishment, and technical support, to maintain optimal caster performance and high-quality output.

Modern Hot-Strip Mill with Intelligent Control Systems

The hot-strip mill includes a single-stand 4-high reversing roughing mill with attached edger and patented Encopanels. The first two finishing mill stands and the strip cooling system have been upgraded, along with a comprehensive Level 1 and 2 automation system.

The modernized hot-strip mill allows thyssenkrupp Steel to improve yield and expand its product portfolio, including high-strength steel and grades for the e-mobility sector. This is made possible by the Encopanels, which retain heat in the transfer bar, increased rolling and bending force at the finishing mill, and the precise Level 1 and Level 2 automation system.

The mill enhancements are managed by advanced automation solutions, such as the Contour and Flatness Optimizer. Together, these systems ensure precise control of the strip rolling process, while maintaining high quality, productivity, and stable operations, even when process requirements change, such as product dimensions or steel grades. The extended laminar cooling section, equipped with precise Level 2 strip cooling models, allows for accurate cooling profiles and temperature control, enabling consistent material properties.

Major Modernization Order

The project is part of a broader modernization plan. In 2021, thyssenkrupp Steel ordered a reversing cold mill, the hot-strip mill, and two thick-slab continuous casters from Primetals Technologies. The cold mill produced its first coil in September 2023 at the Bochum site, and slab caster No. 3 is scheduled for 2026.

With an annual production volume of about 11 million tons of crude steel, thyssenkrupp Steel employs around 26,000 people worldwide. The company aims to produce five million tons of CO₂-neutral steel per year by 2030 and achieve full climate neutrality in production by 2045.

- Expands Shagang’s market reach into the high-quality rod product market

- Enables low-temperature thermomechanical rolling

- Significantly improves dimensional tolerance and coil packaging for wire rod products

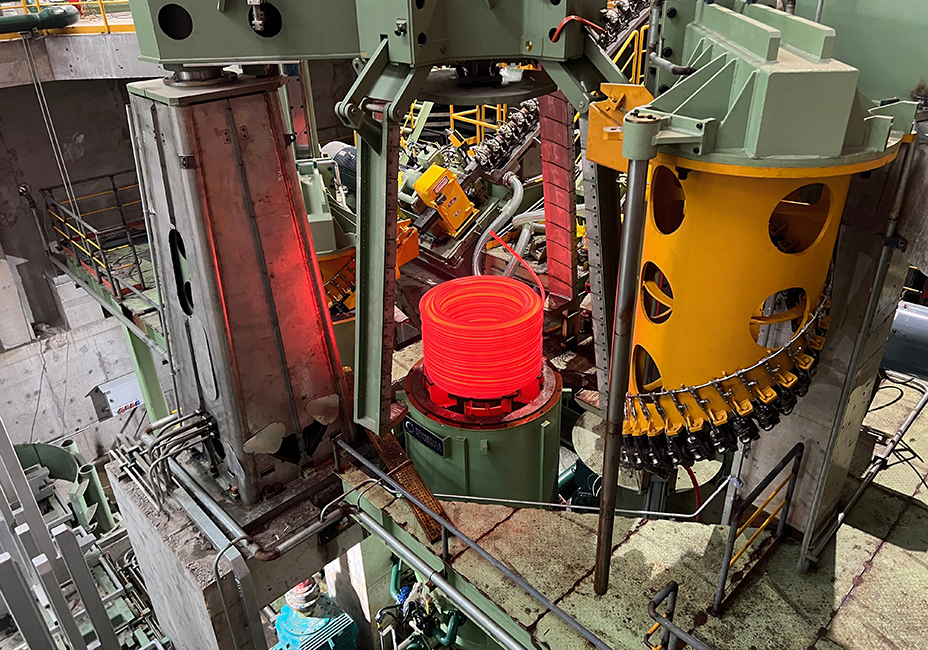

Primetals Technologies has received the final acceptance certificate (FAC) from Jiangsu Shagang for the successful upgrade of the wire rod outlet and the rebuild of the Morgan Reducing/Sizing Mill within line No.3 at the company’s sixth mill in Zhangjiagang City, Jiangsu Province, China. This project, part of a broader initiative to modernize Shagang’s mills, focused on enhancing dimensional tolerance and mechanical properties. It marks the first of several planned wire rod outlet upgrades across Shagang’s production lines.

Thanks to the modernization, finished rod products achieve improved tolerances and surface quality. Additionally, Jiangsu Shagang has received immediate positive feedback from the end-users regarding metallurgical and dimensional tolerance resulting from the upgrade.

The project’s scope of supply included equipment for the rebuild of the reducing/sizing mill incorporating new guides, a new Morgan Intelligent Pinch Roll and sixth generation laying head, high-speed shear before the reducing/sizing mill, and a comprehensive mechatronics package. Engineering for the water-cooling line, the Morgan Stelmor Controlled Cooling Conveyor, and reform tub area, as well as site supervision services were also included.

Quality Equipment Ensures Quality Product

A key part of the wire rod outlet’s upgrade included a rebuild and relocation of the mill’s Morgan Reducing/Sizing Mill by Primetals Technologies, including upgrades to the external gear box.

The Morgan Reducing/Sizing Mill is a high-performance rolling mill for high-quality steel wire rod that reduces and sizes the wire rod to precise dimensions according to mill production parameters. Its high precision and combination of modern technologies enables low-temperature thermomechanical rolling, allowing a more refined microstructure that can reduce or even eliminate costly downstream annealing processes.

A Long-Standing Partnership

This upgrade marks yet another successful project with Jiangsu Shagang in a 30 plus-year partnership between the two companies. Primetals Technologies has installed nine wire rod mills in Jiangsu Shagang’s Zhangjiagang City location since 1992 and three wire rod mills at the Dongbei location since 2007.

Jiangsu Shagang Group, located in Zhangjiagang City, is a major steel manufacturer founded in 1975. The company produces deformed, special bar, wire, plate, and special forged steel products used in a wide range of industries worldwide.

Photo: Hot coil on the Morgan Stelmor Cooling Conveyor from Primetals Technologies at Jiangsu Shagang’s line No.3.

- Extensive caster revamp enables Chinese producer to expand into high-end plate market

- Single-Roll DynaGap (SRD) and dry-casting segments ensure high-quality thick plate production

A steel producer in eastern China has tasked Primetals Technologies with the supply and implementation of a 1-strand thick-slab continuous caster upgrade. The scope includes key mechanical equipment, a comprehensive Level 1 and Level 2 automaton solution, and implementation services.

The project will expand the continuous caster’s thickness range up to 360 millimeters. With the new equipment, the producer will be able to manufacture plates for heavy-gauge, high-end applications, including the wind turbine sector. Annual capacity will be 1.9 million tons of high-quality slabs, with startup scheduled for mid-2026.

High-Quality Thick Plate Production

The machine will be equipped with Single-Roll DynaGap (SRD) segments from Primetals Technologies, enabling dynamic alignment of individual casting gaps when production parameters such as steel grade, cooling grade, and casting speed change. The SRD segments apply forces of up to 4,000 kilonewtons per roll, ensuring supreme internal microstructures and defect-free, high-quality thick plates.

Smart Segment is Primetals Technologies’ patented continuous bending and straightening concept. Combined with the Eco Star rolls, this solution results in significantly improved slab-surface quality. Featuring an internal cooling system, the Eco Star rolls are able to endure the high temperatures required to minimize surface defects. Additionally, as part of the upgrade, Primetals Technologies will also install new Smart Molds with a DynaWidth mold-width adjustment system, allowing for fast and smooth slab-width changes.

Enhanced Breakout Prevention and Increased Quality

The comprehensive automation solution ensures optimized casting conditions and greater flexibility. The Mold Expert system detects and prevents breakouts while analyzing the casting process inside the mold. Automated DynaGap soft and hard reduction systems allow dynamic roll-gap control to reduce centerline segregation and improve internal strand quality.

The partnership between the producer and Primetals Technologies spans decades and encompasses numerous casting projects.

Key facts: New 1-strand continuous slab caster for Chinese producer

Capacity

1.9 million tons per year

Caster radius

10 meters

Dimension of slabs

250-360 millimeters thickness,1,500-2,300 millimeters width

Steel grades

Piping steel, wind turbine steel, normal ship plate, high-strength ship plate, bridge steel, structural steel, carbon die steel, and alloyed steel

- Upgrade project generates outstanding electrical energy and electrode consumption savings

- Remarkable 4-minute reduction in power-on times

Primetals Technologies has recently received the final acceptance certificate (FAC) for an upgrade of the 60-ton electric arc furnace (EAF) at a facility operated by the Baku Steel Company CJSC group (BSC) located in Baku, Azerbaijan. This project marks a major step forward in optimizing production processes and enhancing operational efficiency.

The Primetals Technologies scope of supply included a burner system with carbon injection technology, the Melt Expert electrode control system, SlagMon tapping equipment for optimized slag detection, as well as advisory services for installation and commissioning.

Remarkable Decrease in Consumption

In 2023, an initial study conducted by experts from Primetals Technologies identified substantial potential improvements through the addition of a fourth refining combined burner (RCB) and a modern electrode control system in the steel producer’s EAF. Building on this feedback, BSC and Primetals Technologies have successfully implemented the upgrade.

Following the successful installation and integration of Primetals Technologies’ state-of-the-art systems, BSC reported impressive results within just a few days of operation. Key improvements include a significant reduction in electrode consumption by more than 20 percent, a substantial decrease in energy consumption, as well as a notable 4-minute reduction in power-on times. These outcomes demonstrate the immediate impact of the upgrade on the efficiency and performance of the steelmaking process.

Increased Process Stability

Melt Expert from Primetals Technologies enables dynamic control over the melting process and increases process stability. The system improves furnace productivity by addressing reduced throughput and efficiency, common issues in steelmaking operations. It also lowers energy consumption, helping to mitigate the high energy costs associated with the melting process.

Ships to more than 20 Countries

With an annual production capacity of 800,000 tons, BSC is the largest steel production enterprise in the Caucasus region. The company manufactures billets, pipes, and construction rebars from carbon and alloy steel, as well as standard and shaped rolled products including channels, angles, I-beams, wire rod, and shaped casts. BSC exports its products to more than 20 countries across Europe, the US, Africa, and Asia.

- Primetals Technologies to supply torch-cutting solution for efficient scrap processing

- Core benefits include zero dust emissions and significantly reduced noise levels

- Enables cutting of bundles of rolled bars

Finnish recycling services provider Konepeikko Oy has awarded Primetals Technologies the contract to supply a new torch-cutting machine for its facilities located at steel producer Ovako Imatra Oy Ab’s premises in Imatra, Finland. This innovative and environmentally friendly solution is part of Primetals Technologies’ latest developments in scrap cutting, and is significantly reducing noise emissions.

Improved Process Efficiency

The scrap cutting machine ensures that Konepeikko Oy is well-positioned to meet the industry’s current and future demand for scrap. According to the World Steel Association, the use of scrap in steelmaking is projected to reach 1,000 million tons annually within a few years. As a result, the need for effective scrap management systems is increasing, aligning with the transition to green steel production.

A highly efficient dedusting system ensures that dust emissions from the cutting process remain well below the limits set by environmental regulations. Additionally, the cutting machine is placed inside a moveable cabin, further reducing noise emissions. This new technology enables Konepeikko Oy to comply with stringent Finnish environmental regulations, which was one of the main influencing factors for its decision, along with improved process efficiency and occupational safety.

Operators control the machine at a safe distance from a desk outside the cutting cabin, supported by a video monitoring system. Predefined cutting programs based on recipes simplify operation and reduce processing times.

Leading Expertise in Torch-Cutting

Konepeikko Oy’s new machine will cut various types of scrap, including billets, blooms, and bundles of rolled bars. Furthermore, the system‘s ability to integrate iron powder into the cutting process allows for cutting of tundish skull, rolling mill rolls, and other hard, high alloy materials.

This advanced technology was developed by experts from former TCT Torch-Cutting Technologies, a Spanish company acquired by Primetals Technologies in August 2023. TCT is renowned for its torch-cutting expertise, offering a wide spectrum of innovative solutions for all kinds of cutting applications in steel plants, rolling mills, forging shops, foundries, and scrapyards.

Konepeikko Oy specializes in recycling, focusing on the acquisition and processing of steel scrap. The company processes more than 50,000 tons of recycled materials annually, and also manages construction waste from demolition sites.

Photo: 3D image of Konepeikko Oy’s scrap-cutting machine from Primetals Technologies. The design accommodates loading from both sides.

- Extensive upgrade of process optimization systems (Level 2) enables production increase from 250,000 to 500,000 tons annually

- Primetals Technologies to execute a carefully crafted three-phase plan for immediate, medium-term, and long-term modernization of Marcegaglia’s minimill in Sheffield, the UK

- Through-Process Optimization study laid foundation for improvement measures

Marcegaglia Stainless Sheffield, based in the UK, has partnered with Primetals Technologies to optimize production processes across its Sheffield minimill. The modernization project aims to double the plant's annual production capacity from 250,000 to 500,000 tons. Several intralogistics systems, process optimization solutions, technology packages, and intelligent sensor systems will be installed at all production units of the meltshop, scrap yard, and the ladle tracking system.

Tailored to Marcegaglia’s Needs

The project is tailored to Marcegaglia's specific requirements, based on a recent Through-Process Optimization (TPO) study conducted by Primetals Technologies. The TPO assessment provided Marcegaglia a comperehensive analysis of the steelmaking plant, identifying bottlenecks and outlining potential improvement measures. A key result of the assessment, the improvement roadmap, highlights recommended actions to achieve a streamlined implementation process.

The TPO study was a key factor in Marcegaglia’s decision to choose Primetals Technologies for this extensive automation upgrade and for the recently awarded electric arc furnace revamping project.

As a first step, Primetals Technologies will install Melt Expert, a fully automated electrode control system for electric arc and ladle furnaces. Mid-term plans include the implementation of process optimization software (Level 2) for the electric arc furnace (EAF), argon-oxygen decarburization (AOD), and ladle furnace (LF) plants, all of which are currently missing from the automation landscape. Long-term plans include the replacement of the electric arc furnace to accommodate the future productivity increase.

A Relationship Beyond System installation

“Marcegaglia chose Primetals Technologies not only for its technical expertise, but also for its commitment to fostering a long-term partnership. This relationship goes beyond system installation to ongoing system updates and development,” said Tom Eades, Engineering Manager at Marcegaglia. The ultimate goal is to increase productivity, which will require introducing an additional production shift. New personnel will be able to gain the necessary knowledge to efficiently run a production unit through Primetals Technologies' new process optimization systems, which provide digitalized knowledge, recommended actions, and training sessions for operators. Marcegaglia intends to start using the standard know-how rules included with all systems, with modifications aligned to operators' best practices as a part of the planned service contract.

Comprehensive Set of Solutions

The scope of supply includes the Scrap Yard Supervisor, which calculates cost-optimized scrap recipes, visualizes process information, and tracks loading processes. Intelligent sensors, such as the Scrap Basket Profile Monitor, monitor specific process steps, identify deviations from standard operating conditions, and notify the operator.

The process optimization solutions EAF Optimizer, AOD Optimizer, and LF Optimizer provide dynamic process control for improved product quality, advanced metallurgical models to meet production-related quality criteria, and detailed calculations of input materials to reduce costs. The Ladle Tracker suggests the most suitable ladle for the upcoming batch, avoiding quality loss caused by residues from previous batches.

Long Stainless Steel of High Quality

Marcegaglia Stainless Sheffield is a global manufacturer of long stainless steel products. The company is known for its ability to provide reliable products of high quality in a wide range of grades, shapes, and sizes. Its stainless steel is a sustainable material with over 90 percent recycled content. Products are melted in Europe using energy sources and raw materials that provide Marcegaglia Stainless’ customers with a carbon footprint lower than industry average.

Marcegaglia will equip all the production units of the minimill meltshop in Sheffield with automation systems from Primetals Technologies.

- Both wire rod mill outlet and bar-in-coil line expand rolling mill capacity for large size products and low temperature thermomechanical rolling

- New eDrive mini-finishing mill increases efficiency through integrated single-family rolling

- Bar-in-coil outlet expands size range to further enhance Baoshan’s market presence

Primetals Technologies has recently completed an installation at Baoshan Iron and Steel in Shanghai, China, for a new combination mill featuring both a wire rod mill outlet and bar-in-coil line to produce 600,000 tons per year of wire rod and bar products. This installation is Baoshan’s first greenfield long rolling investment since the original mill installation in 1998. The new mill is specifically designed to increase rolling mill capacity and expand size range with the wire rod mill outlet handling 7.5-to-29-millimeter rod and the bar-in-coil line handling 8-to-50-millimeter bar.

A New Technology for Increased Rolling Capacity

To reduce downtime, Primetals Technologies utilized four eDrive mini-finishing mills with 250 millimeter ultra heavy-duty roll housings for integrated single-family rolling from a standardized mill train. eDrive is one of Primetals Technologies’ newest long rolling solutions. Its purpose is to expand the already extensive capabilities of the company’s line of long rolling mill products by increasing load-carrying capacity, reducing long-term costs, enabling low temperature thermomechanical rolling, using quick-change roll units, and more.

The project scope included equipment supply, engineering, and site supervision services as an open consortium between Baowu Steel Group and Primetals Technologies. The full list of equipment included four eDrive mini-finishing mills, guide optics, a pinch roll and laying head, the latest high-speed pouring reels, as well as a mechatronics package comprising of the mechanical software necessary for this key equipment.

Dedicated Customer Support

In a letter of appreciation, Tang Jinsong, Director of Long Rolling at Baosteel, expressed his gratitude to Primetals Technologies saying, “During the commissioning period, we received the highly specialized technical support from Primetals Technologies’ site team including rolling process, fluids, and mechanical supervision personnel, as well as careful and personal service from the aftermarket service team. We are deeply satisfied with this and would like to express our sincere gratitude.”

“Primetals Technologies high-speed rod mill eDrive and bar-in-coil technology has been well received and the progress of the project has been highly praised by all parties.”

Baoshan Iron and Steel, a subsidiary of Baowu Steel Group located in Shanghai, PRC, is a comprehensive steel service company specializing in the processing, sales, and technical services of stainless steel and carbon steel alloys, including high quality wire rod products since the late 1990s.

Hot coil during bar-in-coil outlet commissioning.

- New five-year cost-per-ton maintenance contract

- Repair and maintenance of continuous caster equipment and components

- Process improvements to enhance equipment performance and longevity

- Work to be performed at a nearby 40,000-square-foot facility operated by Primetals Technologies

Primetals Technologies has secured a five-year cost-per-ton maintenance contract from Outokumpu Stainless USA, a leader in stainless steel manufacturing. The company will be responsible for the repair and maintenance of Outokumpu’s single-strand continuous casting machine in Calvert, Alabama.

Committed to Process Improvements

This contract marks a significant shift from previous maintenance work. Primetals Technologies will apply its in-depth knowledge of the original equipment and introduce future process improvements. The company is committed to enhancing the performance and longevity of the continuous caster, which it supplied to Outokumpu in 2012. This includes implementing the latest advancements in mold coating and roll overlay technologies.

The maintenance work will be relocated to a nearby 40,000-square-foot facility in Calvert, operated by Primetals Technologies. This move will streamline maintenance operations and provide Outokumpu with additional space in its meltshop for other production activities. Throughout the transition, there will be no disruption to Outokumpu’s production in Calvert or the operation of the continuous casting machine.

Securing this contract, along with a recent caster maintenance agreement from ArcelorMittal Nippon Steel (AM/NS) Calvert, further strengthens Primetals Technologies’ upstream and downstream service offerings in the United States.

Comprehensive Maintenance Scope

The contract covers a wide range of maintenance activities for continuous caster equipment, ensuring optimal equipment performance and longevity. This includes the repair and servicing of molds, oscillators, as well as the bender, bow, straightener, and horizontal segments. Additionally, Primetals Technologies has been tasked with the upkeep of caster rolls (both new and reconditioned), spindles, table rollers, table drive shafts, and all spart-part management.

Primetals Technologies will also apply its innovative Hiper Coat technology to the mold coppers, which offers variable hardness to extend the life of these components. Similarly, its proprietary overlay technology will enhance the performance and durability of the caster rolls. The contract also entails bi-annual strand alignment and reporting, labor and supervision for core equipment maintenance, and operational expert support services.

Access to Advanced Technology

Another advantage that Primetals Technologies offers is the option for its customers to access remote assistance through its advanced operations-management platform called Through-Process Optimization. Additionally, the m.space e-services platform allows operators to order spare parts online, access helpful training sessions, and centralize plant documentation.

Furthermore, the Maintenance and Asset Technology (MAT) platform offers a suite of tools for real-time tracking of mold copper and roll fleets. Developed by Primetals Technologies, MAT’s predictive maintenance scheduling employs reliability-centered maintenance strategies to address failure modes and optimize asset lifetime. MAT also includes graphical work order tracking, forecasting to boost overall productivity, and a KPI dashboard for insightful reporting. Designed for portability, MAT can be operated on tablets, ensuring on-site and offline accessibility.

About Outokumpu

Outokumpu is accelerating the green transition as the global leader in sustainable stainless steel. Its business is based on the circular economy: Outokumpu’s products are made from 95 percent recycled materials, which it then turns into fully recyclable stainless steel. This steel is utilized in various applications across society, including infrastructure, mobility, and household appliances. In the US, Outokumpu operates America’s most advanced stainless-steel mill in Calvert, Alabama. With an extensive range of products and industry-leading technical support and services, Outokumpu is the second-largest producer of sustainable stainless steel in the United States. Learn more at: www.outokumpu.com

- Primetals Technologies celebrating 100 installations of electrode control system Melt Expert

- Key success factors are a high level of precision and effective optimization of electric arc furnace melting processes

- Major benefits for steel producers include productivity gains and cost-savings stemming from lower consumption figures

Athletes who excel at the 2024 Summer Olympics in Paris all have certain characteristics in common – they are precise and effective, and they showcase world-leading skills in their respective discipline. Interestingly, all of these features can also be found in Primetals Technologies’ Melt Expert electrode control system for electric arc furnaces (EAFs) and ladle furnaces (LFs).

Melt Expert customers worldwide benefit from increased productivity, reduced energy and electrode consumption, as well as lower production costs. Simply put, the leading system for optimizing melting processes is a game-changer for steel producers wanting to get the most out of their EAFs and LFs. Recently, Primetals Technologies celebrated its 100th Melt Expert installation at a customer’s site in Turkey. All of these implementations were accomplished within the last four years.

100 Melt Expert Installations

The recent Melt Expert installation at an EAF in Turkey is a significant milestone. Melt Expert enables dynamic control over the melting process, increases process stability, and helps the meltshop staff to overcome scrap fluctuations. The integrated Foaming Slag Manager and the Dynamic Spray Cooling model ensure additional process control and efficiency improvements. The comprehensive diagnostics package provides operators with detailed melt diagnostics, electrode consumption figures, and key performance indicators via an intuitive dashboard.

Precision and Control in Melting Processes

Automation experts from Primetals Technologies have spent years of hard work to perfecting Melt Expert’s performance, making it the true champion in the field of electrode control systems for EAFs and LFs. Melt Expert offers numerous benefits to process engineers, plant managers, and maintenance personnel – it significantly increases furnace productivity by addressing the common problem of reduced throughput and efficiency in steelmaking processes. It also tackles the high energy costs associated with the melting process by lowering the consumption of electrical energy. The system ensures the accurate reproduction of a predefined melting process, solving the problem of operational inconsistency and lack of precision. Moreover, it optimizes the melting process by improving overall furnace performance and output quality.

Ensuring Peak Performance

Just like sports equipment, Melt Expert must stay in shape to continuously unfold its full potential. Primetals Technologies offers worldwide service support, including on-site assistance, to keep the system and its settings optimally adjusted to changes in factors such as scrap density and quality. Service contracts provide troubleshooting support, system maintenance checks, optimization based on data analysis, and a guaranteed response time.

By signing an annual service contract, steel producers benefit from several advantages. A dedicated, expertly staffed support hotline helps to resolve any production-related issue swiftly and comprehensively. Remote live support gives specialists from Primetals Technologies immediate access to critical data for analysis and insight that may not be known to the customer.

The Melt Expert electrode control system has been installed 100 times at electric arc and ladle furnaces.

- Primetals Technologies to supply 2-strand continuous slab caster with optimized roll geometry

- Will be designed for both conventional and silicon steel production

- Third large casting project in three months demonstrates the close and decades-long collaboration between Baosteel and Primetals Technologies

The world’s largest steel producer, Baosteel, a part of Baowu Group, already operates more than 20 casters supplied by Primetals Technologies. The close collaboration, based on mutual trust, was established in the 1990s. On June 18, 2024, Baosteel signed a contract with Primetals Technologies for the latest continuous casting project, this time for a plant in China’s Shanghai region. It is the third caster order from Baowu Group in three months, a fact that further underscores the strong partnership between the two companies.

The new continuous caster No. 6 will produce both conventional and silicon steel grades for various industries including home appliances and automotive. Primetals Technologies will supply the mechanical equipment and a comprehensive scope of Level 1 and 2 automation systems, and will provide construction and implementation services.

Next-Level Continuous Caster Design

A well-balanced combination of sophisticated mechanical design and future-proof automation and digitalization solutions is essential for producing demanding steel grades. Baosteel’s new caster will feature several innovative technologies – this in combination with Primetals Technologies’ established continuous casting expertise and innovation leadership, underscored by a large number of patents, were some of the key factors behind Baosteel’s choice of supplier.

Highly Innovative Solutions

Experts from Primetals Technologies will establish the ideal caster roll geometry already at the design stage. This is thanks to a ground-breaking model recently developed by Primetals Technologies, which reduces mold level fluctuations stemming from unsteady bulging by 50 percent, leading to both higher casting speeds and greater productivity.

A comprehensive suite of automation and technology solutions ensures that Baosteel’s new caster will produce slabs with top-level inner quality – an important feature for the manufacture of demanding silicon grades. The Smart Mold, a high-performance cassette-type mold, will be configured with the DynaWidth online mold-width-adjustment system for flexible and fast slab-width changes. Together, these systems make sure that high-quality conditions are met early in the casting process. An electromagnetic stirrer is a key part of the mechatronics package and allows for enhanced inner-strand quality.

DynaPhase, Dynacs 3D, and DynaGap Soft Reduction 3D are dynamic secondary cooling and soft-reduction packages, which drastically contribute to quality improvements by calculating thermodynamic effects such as conductivity, density, and strand temperature.

Continuous Improvement of Product Quality

Several expert systems round off the extensive scope of automation and technology solutions. The computer-aided quality control system Quality Expert tracks, controls, and supervises quality-related data. This technology also makes quality prediction for the cast products, contributing to continuous improvement of product quality. The Nozzle Expert checks the condition of the secondary cooling system online and detects clogged nozzles and leakages with high accuracy.

A Wide Range of Flat and Wide Products

Baosteel is a part of the China Baowu Steel Group Corporation, a Fortune Global 500 enterprise. The company operates several plants, including locations in Shanghai, Wuhan, Meishan, and Zhanjiang. Baosteel’s product portfolio encompasses a wide range of flat and long products based on carbon, low-alloyed, alloyed, and silicon steel grades for use in various applications.

Primetals Technologies will supply Baosteel with a 2-strand continuous caster designed for both conventional and silicon steel production.

Key facts: Baosteel’s 2-strand continuous caster

Capacity

2.35 million tons per year

Radius

9.5 meters

Metallurgical length

37 meters

Dimension of slabs

230 x 900 to 1,450 millimeters

Steel grades

silicon (NGO, GO), automotive, ultra-low-carbon, low- and medium-carbon, peritectic

- Primetals Technologies’ first-ever EAF Quantum started up 10 years ago at TYASA in Mexico

- Energy-efficient and reliable operation has resulted in an impressive 77,000 heats to date

- 15 EAF Quantum furnaces in operation worldwide, with more currently being constructed

Mexican steel producer Talleres y Aceros S.A. de C.V. (TYASA) and Primetals Technologies have recently reached a milestone for the world’s first EAF Quantum plant in Ixtaczoquitlan, Mexico. On May 7, 2024, the 100-ton electric arc furnace had been in operation for 10 years, boasting some 77,000 heats and a total production of almost eight million tons.

“We are happy to celebrate this milestone achievement together with Primetals Technologies,” says Oscar Junior Chahin, Co-CEO of TYASA. “Back in 2014, our clear target with the meltshop investment was to significantly increase our annual production while keeping operational costs down by utilizing the low power consumption levels of the EAF Quantum. 10 years later, we are pleased to say that the targets have been met, and the EAF Quantum has exceeded our expectations in terms of reliability and efficiency.”

Lower Operating Costs

Several technological innovations enable the EAF Quantum to reach remarkable performance figures. The scrap preheating system shortens the power-on times compared to conventional electric arc furnaces, where the scrap is charged cold. The EAF Quantum’s scrap-preheating technology utilizes off-gas from the production process. Less energy is therefore needed to melt the scrap, resulting in lower operating costs as well as reduced CO2 emissions.

The EAF Quantum can achieve power consumption figures below 300 kilowatthours per ton – with a power-on time of less than 29 minutes and a tap-to-tap time of less than 33 minutes.

Remarkable Tap-to-tap Time

There are 15 EAF Quantums in operation across the world to date, and several furnaces are currently being constructed and implemented. Several of these plants have recently attracted attention within the industry as they are showcasing remarkable performance figures. As an example, the EAF Quantum implemented at Chinese steel producer Guilin Pinggang has achieved tap-to-tap times of 31 minutes at power-off times of 4 minutes.

A Complete Minimill

Founded in 1985, TYASA is a privately owned company with two sites, the production location in Ixtaczoquitlan and a service centre in Mérida, the capital city of the Mexican State of Yucatán. With some 2,400 employees, TYASA produces special steel grades, flat steel, coated steel, and items for the construction sector.

Primetals Technologies has supplied TYASA with a complete minimill – the EAF Quantum, a twin ladle furnace, a twin vacuum degasser, and a continuous casting machine – as well as a reversing cold mill. TYASA has also ordered a CASTRIP production line, which is licensed by Nucor. To process strip from the CASTRIP line, the Mexican steel producer awarded Primetals Technologies with a contract to implement a combined galvanizing and color coating line in 2018.

TYASA’s EAF Quantum from Primetals Technologies has produced 77,000 heats since 2014. The EAF Quantum is characterized by lower operating costs and reduced CO2 emissions.

The EAF Quantum is designed to charge scrap via the innovative shaft into the operating furnace at the optimal time slot during operation. This is resulting in ongoing operation with ideal flat-bath conditions.

- Circular Pelletizing Technology (CPT) revolutionizes pelletizing – has established new standard in cost-efficiency

- First reference plant producing at full capacity in India

- Low cost, low footprint alternative to conventional pelletizing plants

Indian iron ore mining company Essel Mining and Industries Limited (EMIL) recently granted the final acceptance certificate (FAC) to Primetals Technologies for its Circular Pelletizing Technology (CPT) plant located at its facilities in Basantpur, Odisha state, India. CPT is the world’s most compact pelletizing plant for the production of high-quality pellets, featuring an indurating furnace with unique circular design.

The CPT plant – the first of its kind – was successfully put into operation in October 2020, in midst of the pandemic. Since then, there has been an ongoing ramp-up of the production capacity. “With the support of the Primetals Technologies team, we were able to optimize pellet production and have continuously improved both the production capacity and pellet quality. We are still exploiting the full potential of the CPT pelletizing system.” says Pavan Kumar Kakani, Joint President and Unit Head of the EMIL plant in Basantpur.

With a design capacity of 1 million tons per year, the CPT plant processes local iron ores to produce pellets for both the export and domestic market.

Reduced Space Requirements

A CPT plant ensures that space requirements for the induration furnace are reduced by 50 percent compared to conventional pelletizing plants. As a result, the weight of the equipment and the building structure are significantly lower. The pelletizing process required less energy, as the CPT process is designed to optimize the thermal efficiency of the recycled hot process gas. This leads to lower operational expenses (OPEX). Primetals Technologies’ scope of supply included the complete plant design, full basic (Level 1) and process (Level 2) automation systems, as well as advisory and startup services including construction works and supervision during implementation.

A Fortune 500 Member

Established in 1950, Essel Mining and Industries Limited (EMIL) is part of the Aditya Birla Group, a global conglomerate and Fortune 500 member. Aditya Birla Group is active in a wide range of sectors including metals, chemicals, textiles, cement, and renewable energy. One of India’s largest mining companies, EMIL is also a producer of noble ferro alloys.

- Primetals Technologies has implemented a push-pull pickling line for strip thicknesses from 1.8 to 15 millimeters and process speeds of up to 200 meters per minute

- Enables a very wide product mix usually possible only with two conventional continuous pickling lines

- In-line skin-pass mill for enhanced control of strip flatness

Primetals Technologies has recently implemented the world’s largest push-pull pickling line (PPPL) at Chinese steel producer HBIS Tangsteel ’s steel plant in Laoting, Hebei province, China. The first pickled coil was successfully produced in December 2023. Primetals Technologies provided the full mechanical and electrics and automation scope and was responsible for engineering as well as advisory services for the implementation.

Extremely Wide Product Range

The core aim of Primetals Technologies’ push-pull pickling line is to enable an extraordinarily wide product range in terms of strip dimension, steel grade properties, and production capacity. This is normally achieved by operating both a conventional continuous pickling line and a PPPL in parallel. As a result, Primetals Technologies’ PPPL offers a clear advantage over conventional push-pull pickling lines from a flexibility perspective.

HBIS Tangsteel’s PPPL features an in-line 4-high single-stand skin-pass mill. A flatness control system adjusts the mechanical properties by allowing for controlled elongation. Thanks to the skin-pass mill, PPPL operators have even more control over strip flatness.

Maximized Throughput

Supported by an innovative solution for automated analysis and control of the pickling process, personnel at HBIS Tangsteel now have an extensive overview of all aspects of the process and are able to control it in a highly precise way. A part of the comprehensive Level 2 automation solution, the system is backed by a sophisticated pickling software model that considers numerous parameters related to the incoming strip. It was designed to ensure optimal operating conditions regarding temperature, pickling levels, flows, and turbulence. The application of the pickling model leads to a major increase in throughput capacity while ensuring optimal energy use and minimized consumption of pickling fluid.

The PPPL also features a turret-head-type side trimmer processing thicknesses from two to eight millimeters. This type of highly effective trimmer increases the throughput and maximizes strip-edge quality.

Ships to more than 100 countries

The backbone and largest steel subsidiary of HBIS, HBIS Tangsteel is one of the biggest state-owned iron and steel enterprises in China. The main products of Tangsteel are: hot-rolled and cold-rolled sheet, galvanized sheet, medium and heavy plate, as well as bar, wire, and section products, which are widely used in automobiles, appliances, machinery manufacturing, infrastructure, bridge construction, and other sectors. The products are shipped to more than 100 countries across the world. Tangsteel is committed to providing the most valuable steel materials and comprehensive service solutions for downstream businesses.

- Complete wire rod mill with state-of-the-art mechanical and automation technology

- New generation of No-Twist Mill (NTM) with individually driven stands

- First Morgan Rod Reducing/Sizing Mill (RSM) in Turkey compatible with the tight tolerance requirements in the high carbon tire cord market

- Long rolling (LR) Process Expert, a comprehensive modular Level 2 automation solution, optimizes production processes

- From first hot coil to final acceptance of contract within 20 days

Primetals Technologies has received the final acceptance certificate (FAC) for a wire rod mill modernization project at Kaptan Demir Çelik (Kaptan Iron & Steel, part of Kaptan Group) in Marmara Ereğlisi, Turkey. With an annual capacity of 650,000 tons, the facility will process carbon, austenitic stainless steel, and cold heading grades.

The project has expanded Kaptan’s portfolio to include such value-added products as coiled rebar, fine grain rebar, and welding wire for the engineering and automotive industries in both domestic and export markets. The new equipment allows Kaptan to be a quality leader on the world market.

Setting a new standard

The startup was remarkably quick. It took only 21 days from start of hot commissioning until the first saleable product. This record-setting implementation has established a new industry standard and was made possible thanks to an experienced project team as well as close and effective collaboration between Primetals Technologies and Kaptan Demir Çelik.

The equipment’s technological advantages, along with prominent aftermarket services, ensured by Primetals Technologies’ local presence in Turkey, were two of the main influencing factors when Kaptan chose Primetals Technologies as supplier in 2021.

Consistently high quality at lower energy costs

The new wire rod outlet has increased Kaptan’s overall production and finishing speeds. The mill rolls up to 105 tons per hour at speeds of up to 110 meters per second. Kaptan can now offer quality carbon products ranging from 4.5 to 26 millimeters in diameter at an expanded range of rebar sizes from 6 to 20 millimeters.

Kaptan’s new mill has the distinction of being the first to combine a Morgan Rod Reducing/Sizing Mill (RSM) with a next-generation No-Twist Mill (NTM) consisting of individually driven stands. This configuration allows Kaptan to consistently deliver high-quality finished products at reduced alloying and energy costs. The RSM can also achieve the tight tolerances required for the high carbon tire cord market. Additional production advantages result from a metallurgical in-line heat treatment process using high-precision Morgan Water Boxes and Morgan Stelmor Controlled Cooling Conveyor.

Streamlined operations

Primetals Technologies’ electrical and automation supply included the main and auxiliary drives and motors, new Level 1 automation system with human-machine interface (HMI), new Level 2 Process Expert automation, as well as the central and local operator stations.

A state-of-the-art Level 1 automation solution from Primetals Technologies helped to minimize the total shutdown period of the wire rod mill and to realize a fast and easy production ramp-up. Using a tablet-style mobile control panel from Primetals Technologies, operators can safely control local equipment for inspection, adjustment, and other maintenance-related tasks.

The automation scope is rounded off by a cost-effective Level 2 process automation system. The Long Rolling (LR) Process Expert, developed by Primetals Technologies, is a platform for production management. Modules can be added to provide insights into material tracking and quality control. They are based on actual production data. The system features a simple interface to evaluate plant performance and to execute production process related optimization measures. Together, these systems pave the way for greater interconnectivity and more effective plant management.

The project scope also includes operating parts, guide equipment, offline devices for stand preparation, media systems, engineering services for other components, advisory services for construction and implementation, and training of personnel.

Ships to more than 100 countries

Kaptan Demir Çelik began production on its first rolling mill in 1964 and continues to expand its presence at Marmara Ereğlisi. Kaptan’s products are used in more than 100 countries worldwide. With this reach, they have put themselves in pole position to lead the European market.

NO-TWIST, RSM, and Stelmor are registered trademarks of Primetals Technologies in certain countries.

- 20-high HZ-mill from Primetals Technologies will enable Anshan Iron and Steel Group to realize grain-oriented silicon steel grades of exceptional structural quality

- Strategic investment allowing the producer to benefit from the rapidly growing market of electric vehicles

Recently, Primetals Technologies was selected by Chinese steel producer Anshan Iron and Steel Group to supply a reversing cold mill for its steel plant in Anshan City, Liaoning province. The new 20-high HZ-mill will produce high-strength silicon steel for the fast-growing electrical steel market.

Increased productivity

The HZ-mill, an advanced split-housing ZR-mill from Primetals Technologies, has several benefits over a conventional ZR mill. For example, the HZ-mill is designed with a large gap opening, which results in easy strip threading and a smooth recovery after strip breakages. Moreover, the roll-diameter configuration is tailored to individual needs, and the HZ-mill features a Double AS-U shape control system for a stabilized rolling process and an increase in productivity.

The HZ-mill lets operators utilize almost the entire range of the work rolls, regardless of the diameter of the intermediate rolls. This results in more options – another advantage over the monoblock ZR-mill.

A leading supplier

A regional subsidiary of parent company Ansteel, Anshan Iron and Steel Group has a comprehensive product portfolio that includes hot-rolled sheet, cold-rolled sheet, galvanizing sheet, color-coating sheet, cold-rolled silicon steel, heavy rail, seamless pipe, section, and construction steel. Anshan is the leading supplier of steel to the automotive, bridge, and nuclear power industries in China. Additionally, Anshan holds an important position in the markets for railway products, home applicants, and steel for the energy industry.

Representatives from Ansteel and Primetals Technologies during the contract signing ceremony for the 20-high rolling mill.

- Upgrade of 40-ton AOD converter shop results in increased productivity, improved product quality, and increased lifetime

- Startup scheduled for beginning of 2025

Italian special stainless steel producer ASONEXT has tasked Primetals Technologies with the revamp of its 40-ton argon-oxygen decarburization (AOD) converter shop at its facilities in Brescia, Italy. Primetals Technologies previously executed a comprehensive study for ASONEXT on the existing AOD process. The study provided the steel producer with certain pieces of advice that are already resulting in a significant improvement to the production process. As part of the study, Primetals Technologies proposed the revamp of ASONEXT’s AOD converter, which is now about to be realized.

Well-established AOD expertise

As the leading provider of AOD equipment, Primetals Technologies has supplied the majority of the world’s AOD plants. Tried-and-tested expertise related to the AOD process as well as the sound reference base were two reasons behind ASONEXT’s choice of supplier. The startup of the new converter is scheduled for the beginning of 2025. Primetals Technologies is responsible for the engineering, scope of supply of production equipment, and supervision of construction work and implementation.

New geometry results in productivity boost

ASONEXT is targeting small production lots of special stainless steel grades and alloys for high-tech applications. This niche poses a challenge to the production process, including the performance of the AOD converter. Primetals Technologies will design a new type of vessel geometry, resulting in a 30-percent increase of the inner vessel volume. This, in turn, ensures improved vessel lining performance and a 12-percent improvement of the reaction volume. Moreover, a new design of the detachable, reinforced top cone will result in a longer lifetime as well as smoother and more streamlined maintenance. A further benefit for ASONEXT is a productivity boost, which is a result of shorter treatment times.

Established in 1971, ASONEXT has an annual production capacity of 150,000 tons. The Italian producer serves several markets including the aerospace, ship building, and petrochemical industries.

The revamped AOD converter from Primetals Technologies ensures increased productivity.

- Primetals Technologies to supply EAF Ultimate with an annual capacity of 1.6 million tons of liquid steel

- Comprehensive automation system enables detailed process control and calculation of carbon footprint

- Huge step for the production of green steel in Austria

voestalpine has placed an order with Primetals Technologies for a 180-ton EAF Ultimate to be implemented at the Austrian steel producer’s site in Linz, Austria. Startup is scheduled for 2027. The EAF Ultimate will be playing a key role in voestalpine’s green transition program “greentec steel.” As a first step in this ambitious decarbonization program, one electric arc furnace will be built at each of voestalpine’s sites, in Linz and Donawitz.

Latest generation of EAF based steelmaking plants

Primetals Technologies will supply the complete EAF Ultimate equipment, a dedusting system, a waste-heat recovery system, electrical grid stabilization, and material handling for alloying materials and additives. The order also includes full Level 1 and 2 automation, a power supply system including a static synchronous compensator (STATCOM) for optimized grid stabilization, and the LiquiRob robotic system, which increases efficiency and occupational safety at the plant.

The EAF Ultimate will be designed to incorporate industry-leading solutions for environmentally friendly steel production. For example, the heat recovery system will convert much of the waste heat into steam, which is then fed back and used in other production units.

“We are very happy to strengthen our close and long-lasting partnership with voestalpine and to support them on their way to becoming CO2-neutral. The EAF Ultimate is part of our latest generation of electric steelmaking plants and is well-known for its raw material flexibility, fully automated operation, advanced control systems, and environmental efficiency. With this technology, voestalpine is set for a future of decarbonized steel production,” says Andreas Viehböck, Head of Upstream Technologies at Primetals Technologies.

In August 2022, Primetals Technologies announced a significant contribution to Salzgitter’s SALCOS green steel transition project in Germany. This collaboration and other recent references as well as expertise in both the production of advanced steel grades and leading automation solutions were the most important factors influencing the decision to choose Primetals Technologies as the supplier for the new electric arc furnace and meltshop equipment.

State-of-the-art automation system

The automation scope includes the latest generation of the web-based DCS process control system, which unites the engineering and operational teams in the same environment. This system ensures intuitive system operation and best-in-class support in maintenance-related topics. The Level 2 automation system is state-of-the-art, resulting in superior process control and the possibility to calculate the carbon footprint of the electric steelmaking plant.

Global market leader

Headquartered in Linz, Austria, voestalpine is a global steel and technology group and a leading partner to the automotive and consumer goods sectors as well as the aerospace and oil and natural gas industries. The company is also the global market leader in railway systems, steels for the manufacture of tools, and special sections. voestalpine is committed to global climate goals and has a clear plan for decarbonizing steel production via its greentec steel program.

The EAF Ultimate is equipped with various features to increase the degree of automation, boost productivity, and contribute to increased safety for operators.

Contact information

E-mail: info@primetals-ru.com

Legal address: 10 Gilyarovskogo str., bld. 1, 4th floor, Moscow, 129090

Physical address of the Moscow office: 10 Gilyarovskogo str., bld. 1, 4th floor, Moscow, 129090

Moscow office phone #: +7 (495) 114-55-18

Physical address of the Ekaterinburg office: Karl Liebknecht str., bld. 4, Ekaterinburg, 620075

Ekaterinburg office phone #: +7 (343) 379-23-95